A few miles down the road from me there is a large open space on the side of the road, and most Sundays it becomes a local marketplace for a bit of everything. Often this includes old tools, and every once in a while out of the boxes of rusty hammers and handsaws there is something which looks like it could be used in my shop. Such was the case with an adze found a few weeks ago.

I wasn’t looking for an adze and the handle had an impressive collection of old nails in it where the last user of it had tried to make it stay on for that last little bit of a project before it was laid aside and never picked up again, but the head was in reasonably good shape, the price was well within my random tool budget, and making a handle seemed a reasonable project to undertake.

Once I had some time to play with it, step 1 was to ditch the old handle before spending a bit of time getting the edge back in working order. With the head ready to go, the next task was to find a piece of wood, and a reasonably grained piece of oak nearly jumped out of the scrap pile to volunteer.

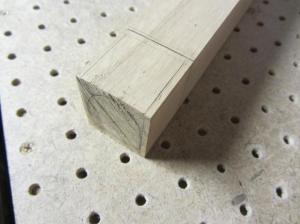

The next step was to mark the head profile on the top of the handle blank (note that that head is the end toward the tip of the tree, this means that if the grain starts to separate you would encounter the splinters as you moved your hands from the bottom to the top of the handle… so in use your hands would generally be sliding over any roughness). This step was then followed by marking off the sides and cutting some stops on the bandsaw.

Next came forming the connection. Simple to say, but a fair bit of effort in practice as this adze has a strapped back and was not nearly as straightforward as a machined head would have been. Quite a bit of carving and trial fitting was required.

With the connection eventually made it was time to go to the lathe and shape the rest of the handle, then run it across the table saw and cut the slot for the wedge (and find another piece of scrap to make a suitable wedge with).

Then it was a relatively simple task to drive the head on the handle down to the shoulder left as a stop and wedge the slot to secure the head. This was followed by trimming off the excess handle and giving the handle a coat of walnut oil to finish.

You must be logged in to post a comment.